Description

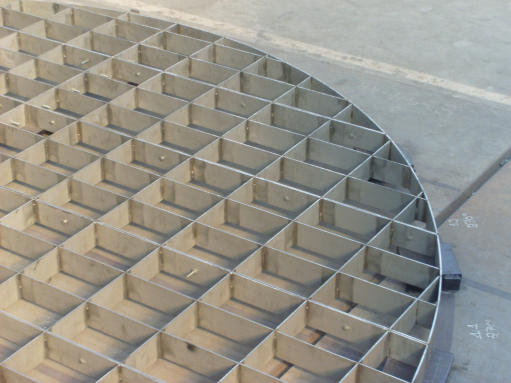

Structured packing is made of rolled corrugated metal sheets, with slopes of 45 or 60 degrees, assembled into packages. These sheets can also be perforated. This type of packing is particularly suitable for using in low pressure and low hydraulic load systems reducing pressure drop and energy consumption.

Structured packings can be made mostly of any produced metal, including carbon steel, stainless steel (types 410, 304 and 316), steel duplex, aluminum, copper alloys, nickel alloys, titanium and zirconium.

They are produced with a large range of sizes and corrugation heights. The packing area can range from 50 m2 / m3 (lowest separation efficiency, highest productivity) to 750 m2 / m3 (highest efficiency, lowest productivity).

Structured packing is produced with two standard angles of corrugation inclination, and can be one of the following types:

- Corrugation angle 45°, for most rectification units

- Corrugation angle 60°, for units with a high liquid velocity, such as heat exchange layers