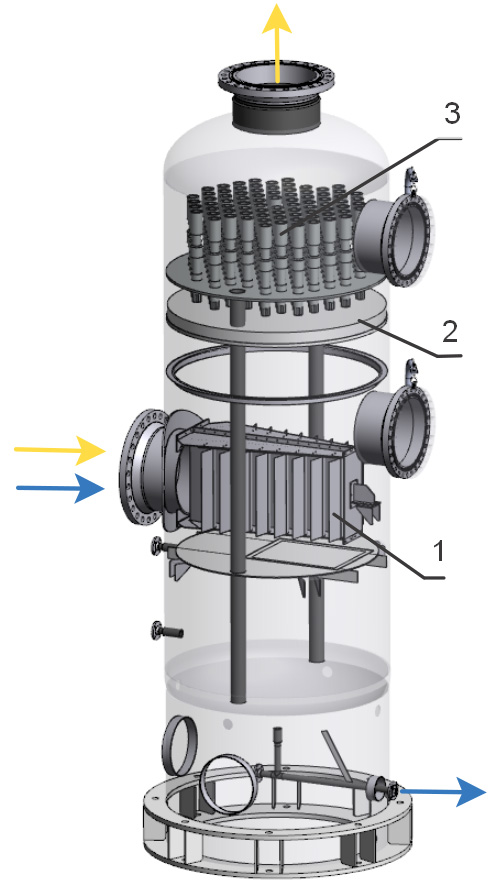

Axial flow centrifugal separation element

(for gas/liquid separators)

Centrifugal gas separators are usually high-performance (in terms of gas flow) devices. Their main advantage is a high speed of gas flow both in separator and in centrifugal elements. In such conditions coalescing section of separator is usually less effective and main part of separation happens within centrifugal elements. Winding the flow intencifies coalescion greatly due to the centrifugal forces that move droplets asides.